can you put wood in a kiln

Click to see full answer. Why is this important.

Home Made Wood Kiln And Working From Home Wood Kiln Solar Kiln Kiln Dried Firewood

Besides firing the clay potteries these kilns are also used to dry wood and tobacco leaves by some people.

. Or you have a bug. Kiln Drying Your Own Wood. You should not put a kiln directly on a wooden floor.

If you are going to locate the kiln somewhere that there will be non-fire-proof surfaces you can make them fireproof by covering them with cement board. And this is what I found out. For example the time re-quired to kiln dry green 44 red oak to a final mois-ture content of 7 percent is two to three times that.

Turn on the convection fan if your oven has one. If youre in a hurry though you can kiln dry wood in a kitchen oven. Can Wood Be Dehydrated.

A layer of cement board strips under those would also be a good idea as they would allow air flow under the boards. Build Smelter or Charcoal Kiln First. Step 1-Prepare the Oven.

It seemed to resolve itself after I restarted the game though. However a wooden floor can be acceptable if you use the stand the kiln was supplied with. Toward the end of drying 40 F above outdoors would be common.

Can you put wood in a kiln. To build the kiln lay poly clear plastic roll on the ground and then build a frame with 2x4 studs on top of it for the lumber to rest on. Species Some species of wood have markedly different drying characteristics than others.

Set up your slumping schedule in the same way you would for glass that is around 14 6cm thick or thinner. Preheat the oven to between 200 and 225 degrees F 95 to 110 degrees Celsius. Make sure there is good support under the legs of the stand.

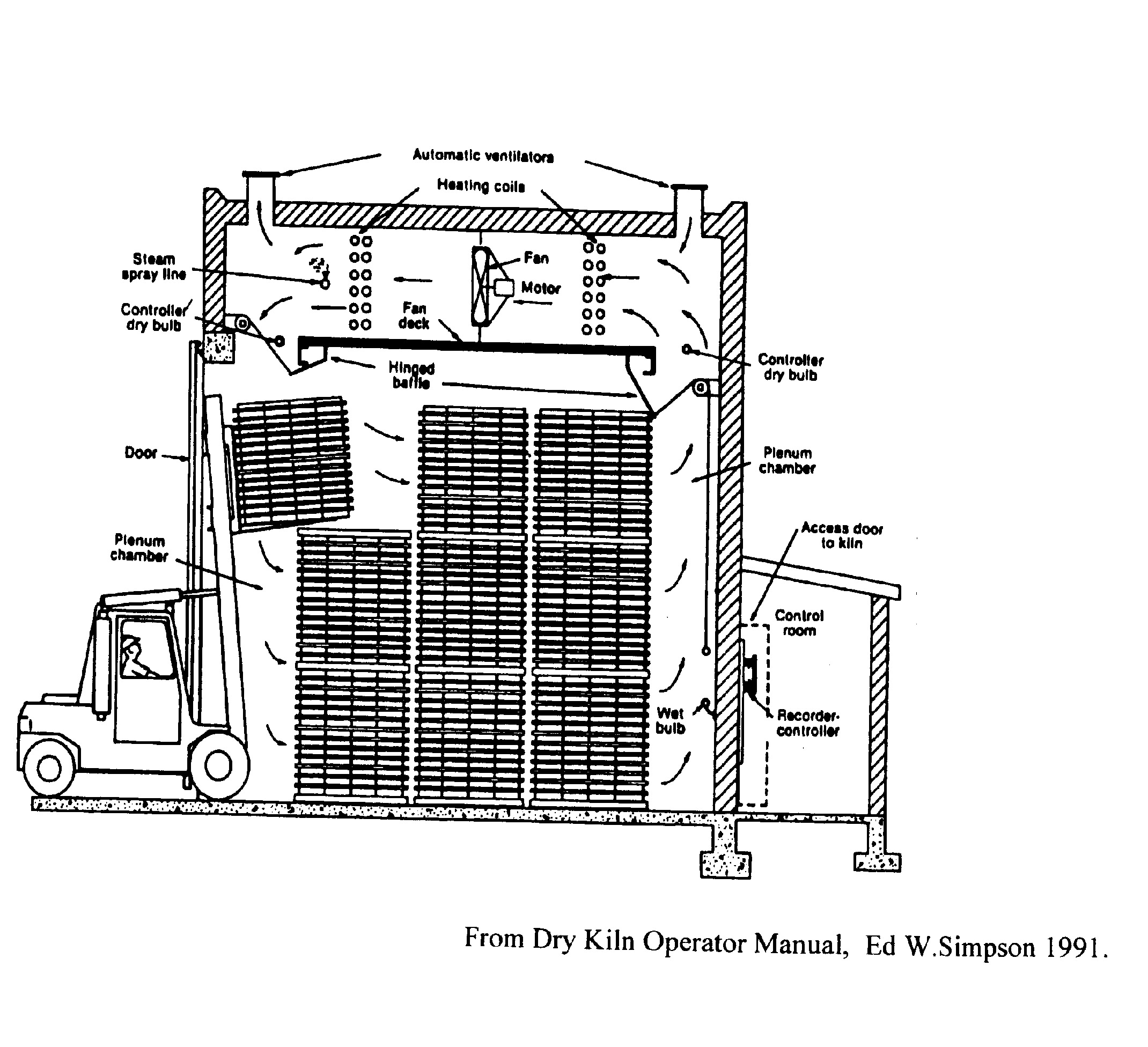

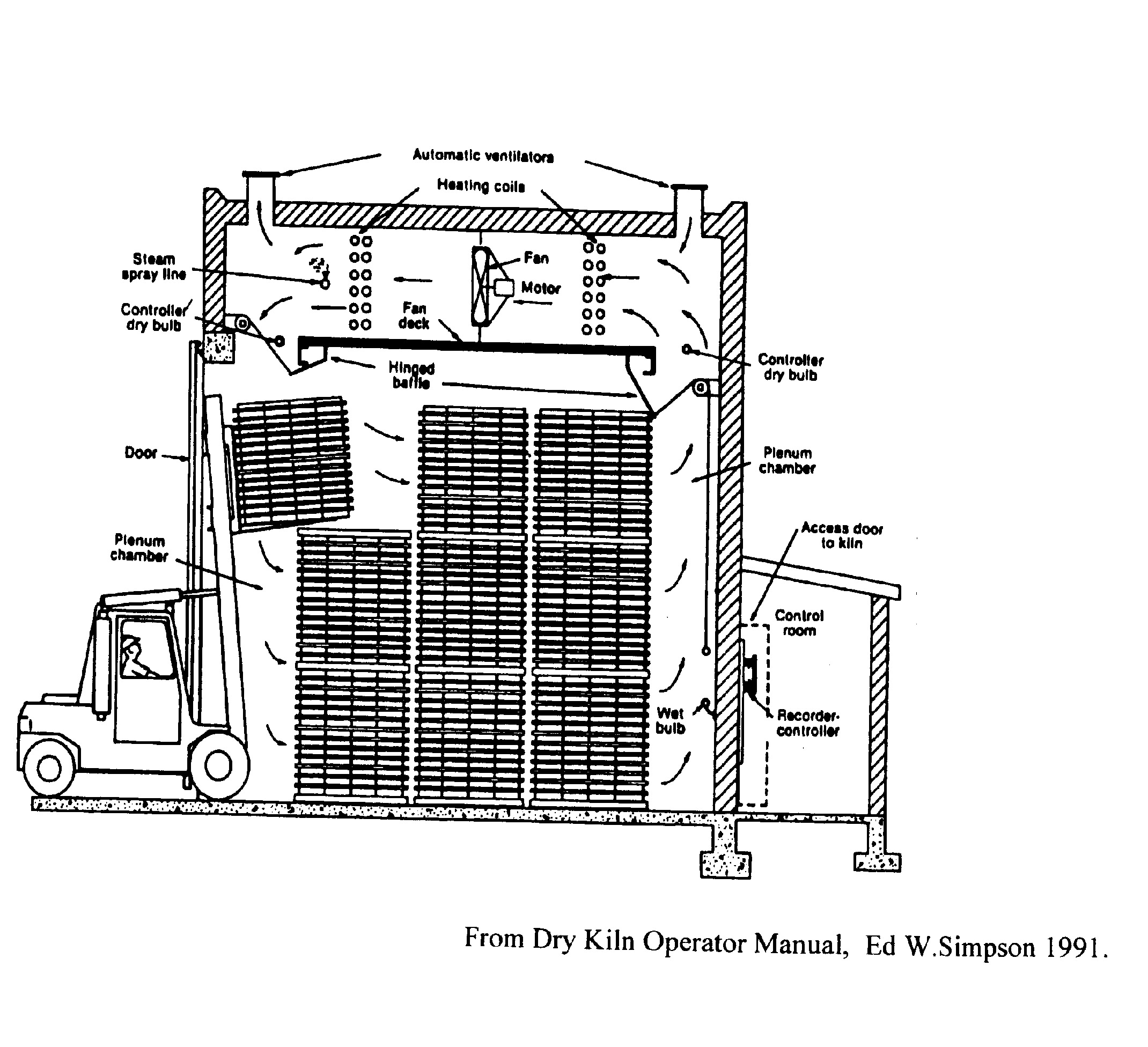

The reason we say this is because the Kiln turns Fine Wood Core Wood and regular Wood to Coal at a pretty quick clip. With a kiln you can control the environment such as temperature humidity and steam levels for a set period of time. Compared to solar kiln drying conventional kiln drying takes considerably less time to dry.

Alternatively you can position your kiln on concrete paving slabs. Our recommendation is that you make the Charcoal Kiln first. Drying wood in a kiln is the quickest and the most efficient way to season wood.

Cement board comes in 4 x 8 sheets usually from Home Depot type places. You can store kiln dried wood outside as long as it is properly stored. While the size of your kitchen oven poses a limitation on the size of the lumber you can place inside it is possible to oven-dry enough wood for small projects.

You can buy kiln-dried pressure treated lumber also called Kiln-Dried After Treatment or KDAT if you dont want to wait as long for the wood to dry before you paint it. This should happen after 15 minutes have passed. Yes there is no problem with that but there are different factors that play a part.

With wet wood the wood will use the energy and the kiln will be cooler. Can you put wood in a kiln. Though the heat can cause the linoleum to become discolored with time.

After a few months bring the wood indoors and finish the drying. An ideal flooring material is concrete. Your kiln will get quite hot with no wood in it as the heat is used for nothing but heating the kiln.

A kiln can only be placed on a wood floor if it is used on its supplied stand and there are at least 2 layers of cement board under it. All surfaces within 3 feet of the kiln need to be fireproof. Here are some recommendations for how to vent a kiln manually.

But if you dont have a kiln then you may improvise with your own kitchen oven. As long as the dehydration process does not cause damage to the items they can be sterilized in a kiln. Can you put rocks in a kiln.

Since it is a special kind of wood it needs to be treated with a little bit of extra care. You can dry air-dried lumber also - just dont expect the few green pieces you want to include at the last minute to dry. Leave enough space to have a standard household dehumidifier at one end and a small fan at the other.

If you are planning to install a kiln in your house you need to collect some essential knowledge about the kiln. Prepare the racks to fit the pieces of wood with plenty of space for air to move. Lumber can be sorted by species moisture con-tent heartwood and sapwood wetwood grain grade thickness and length.

Then youre not carrying the correct thing or youre not using the kiln and are trying to put wood in the smelter. Kiln-dried lumber can be expensive. Kiln-dried lumber does not warp as easily as wet lumber because all of the moisture evaporates during the drying process.

Therefore woodworkers may want to dry their own wood to help assure they are getting the MC they want. That includes the amount of moisture in wood the bunch you have to dry and how fast you need to use it. If your kiln is in a garage or basement you may already have a concrete floor.

Air drying however can take several months and will generally not achieve a low enough MC without the additional step of. As those who have some know kiln dried wood isnt exactly normal wood. One option is for woodworkers to air dry green wood.

Kiln-dried wood is wood that has been dried in an oven kiln. Try fire at 300 degrees Fahrenheit per hour 167 degrees Celsius until the kiln reaches 1250 degrees Fahrenheit 676 degrees Celsius soaking for twenty minutes then turning off the kiln and allowing. I saw dry and process hard maple for the billiards industry.

This technique will be able to dry small pieces of wood as long as you maintain the temperature. Also know can you use a pizza oven as a kiln. If you load same species same size all sawn at about the same time you will get excellent results.

And have at least 2 of non-combustible boards underneath the kiln. In a word- No. The conventional or solar kiln drying process can be used to dry timber to any desired low moisture content but in air drying moisture contents below 18 are difficult to achieve.

Some potters will use a kiln on a linoleum floor surface. I dropped the wood and picked it back up and still the kiln said I did not have processable items. Your stacks of wood should be off of the ground and also be covered at the top to prevent it from getting wet.

When you build the brick box over the old wood stove it will create a kiln that you can easily use to complete your pottery. It is used under tile floors and walls to cement the tile to. I can go on and on about how people misuse these kilns.

There are plenty of items that can be sterilized in a kiln including food preparation supplies metal instruments and wood. You must have an air space between the kiln bottom and the floor. It shoots out one Coal every fifteen or so seconds and you can store up to 25 units of wood at a time.

Allowing you to dry wood to the desired moisture content faster than air-drying. Hence you can also install a kiln in your house. The oven will reduce moisture content in a matter of hours allowing you.

A Simple Approach To Drying Lumber Woodshop News

Homemade Dehumidification Kiln Wood Kiln Solar Kiln Kiln

What Is A Solar Kiln And How Do You Build One

7 Ways To Build A Kiln For Pottery Easy Diy Kiln Ideas

How To Make A Diy Kiln Potterymastery

Drying Wood With Dehumidifier Wood Kiln How To Dry Wood Youtube

Air Dry Vs Kiln Dry Woodworking Blog Videos Plans How To

Logosol Sauno Wood Drying Kiln How To Build And Set Up Youtube

Drying 650 Bf Of Walnut In A Homemade Kiln R Woodworking

Everything You Need To Know About Kiln Dried Wood In A Nutshell

How I Built A Wood Kiln Out Of A 20 Shipping Container Steemit

Diy Firewood Kiln Wood Kiln Kiln Dried Wood Solar Kiln

Kiln Dry Wood At Home Step By Step Method Garden Tool Expert

Home Made Wood Kiln And Working From Home Wood Kiln Wood Shed Wood

Everything You Need To Know About Kiln Dried Wood In A Nutshell

Fundamental Aspects Of Kiln Drying Lumber Oklahoma State University

Treeline Installs A Log Drying Kiln

What Is Kiln Dried Lumber And How Is It Used When Building A Home

My Wood Drying Kiln Wood Kiln Corner Wood Stove Kiln Dried Wood